EKATO

SOLIDFOIL

完美处理连续流动的固体

一种用于连续混合或处理散装物料的叶轮,可避免粘性散装物料结块,并通过表面更新加强固体和进料气体之间的表面接触。

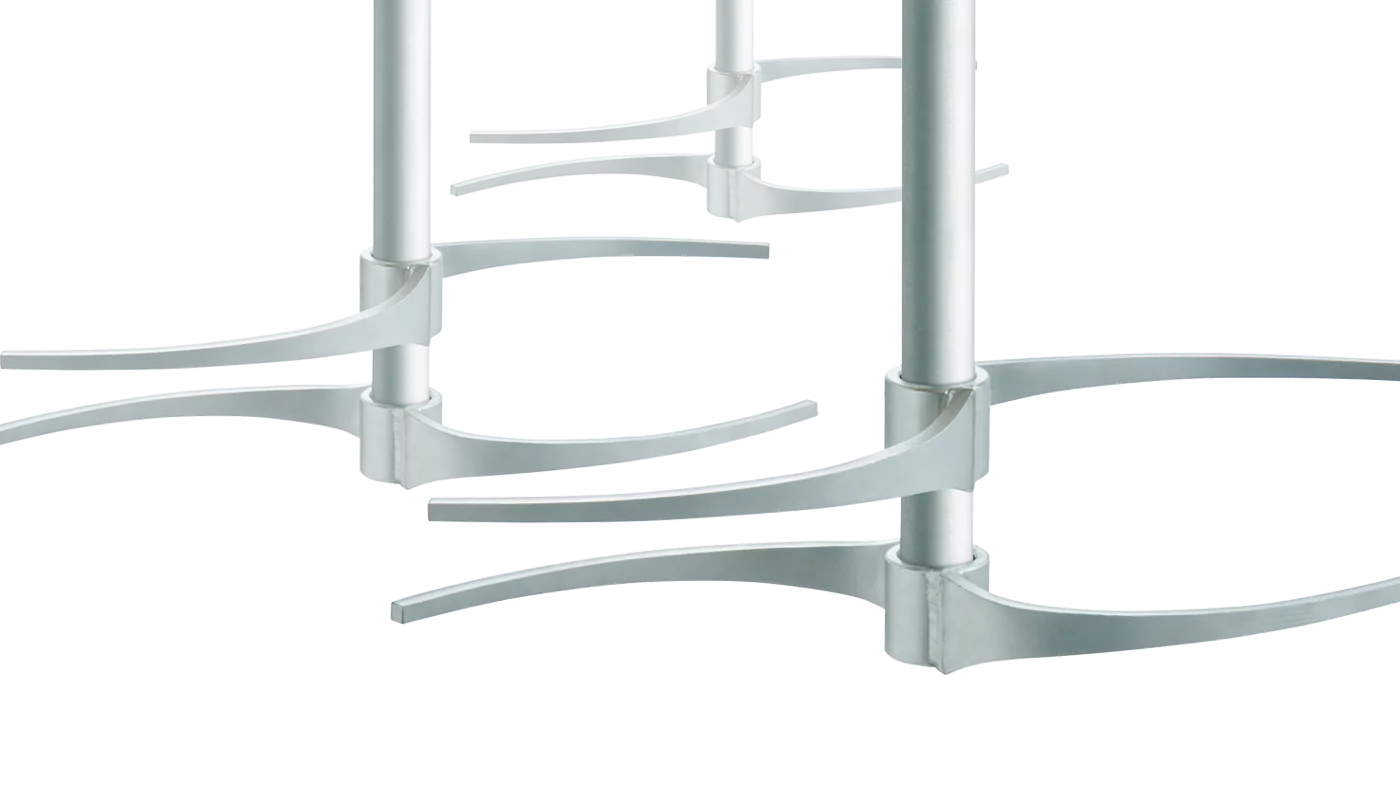

Agitators are normally used during continuous mixing or handling of bulk materials. One the one hand, this is important to allow a mixing process. On the other hand, mixing avoids clumping of adhesive bulk materials or intensifies the surface contact between solid and fed gas (surface renewal) , for example, when stripping monomer residues from polymers. To serve this application, EKATO developed the EKATO SOLIDFOIL as a result of extensive trials in our own laboratory. This impeller is normally applied as a multi-stage mixing system. The unique blade profile diverts the solids axial flow through the vessel into a radial alternate outward and inward direction. As a result, a narrow residence time distribution in the entire vessel occurs, leading to an uniform process result and a better product quality. Simultaneously, the bulk material is permanently restructured which avoids clumping, continuously offering new surfaces for desorption processes for example.

Features

- Uniform process results due to narrow residence time distribution in equipment with vertical flow

- Optimized blade profile that conveys the solids alternately outwards and inwards in a radial direction

- The curvature and adapted height of the blade generates a constant volumetric flow rate along the blade

- The blade geometry can be adapted to the wall friction angle of the product