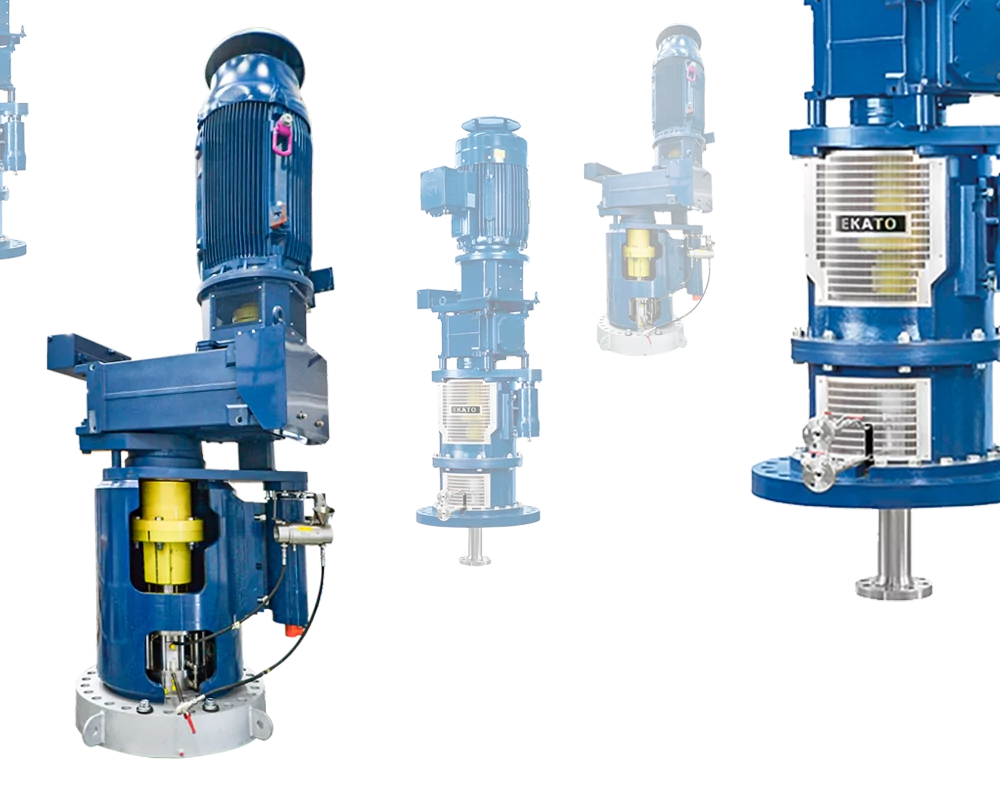

Double-acting Mechanical Seals

Mechanical Seals for Zero Leakage and Challenging Requirements

Liquid Lubricated Mechanical Seal for low Pressure Range ESD34N

Function and application

- Double-acting liquid lubricated mechanical seal for low pressure applications up to 7 bar (abs.)

- Two identical pairs of seal rings in a back-to-back arrangement

- Deliverable with short heat trap for cooling

- Deliverable with water jacket on storage vessel for cooling

Advantages

- Wear parts standardized by modular design

- Double acting, even in low pressure range

- Compact dimensions, suitable for small installation spaces

- Ideal replacement for stuffing boxes

- Designed for cost saving

Working limits

- Operating pressure: vacuum...7 bar (abs.)

- Vessel temperature: -50...+400°C

- Shaft size: 40...220 mm

- Sliding speed: 0...5 m/s

The EKATO ESD34N is most suitable for

- Bulk chemicals

- Polymers

- Pharmaceutical products and cosmetics

- Specialty chemicals

- Formulated consumer products

- Biofuels and bio refineries

- Storage tanks

Double-Acting and Liquid Lubricated ESD34G

Function and application

- Double-acting mechanical seal liquid lubricated

- Two identical pairs of seal rings in a back-to-back arrangement

- Ideal mechanical seal for applications in the medium pressure range up to 40 bar (abs.)

- Use of the modular design opens up many different extension options

- Mechanical seal most commonly used in agitators worldwide

- Deliverable with short heat trap for cooling

- Deliverable with water jacket for cooling

Advantages

- Life cycle cost savings due to extremely solid construction

- FEA ensures optimized stress distribution in every seal ring

- Special spring designs ensure uniform pre-tensioned conditions even in cases of significant agitator shaft displacements

- Almost zero-leakage under the roughest conditions

Working limits

- Operating pressure: vacuum...40 bar (abs.)

- Vessel temperature: -50...+400°C

- Shaft size: 40...220 mm

- Sliding speed: 0...5 m/s

The EKATO ESD34G is most suitable for

- Bulk chemicals

- Polymers

- Specialty chemicals

- Formulated consumer products

- Pharmaceutical products and cosmetics

- Biofuels and bio refineries

- Hydrometallurgy

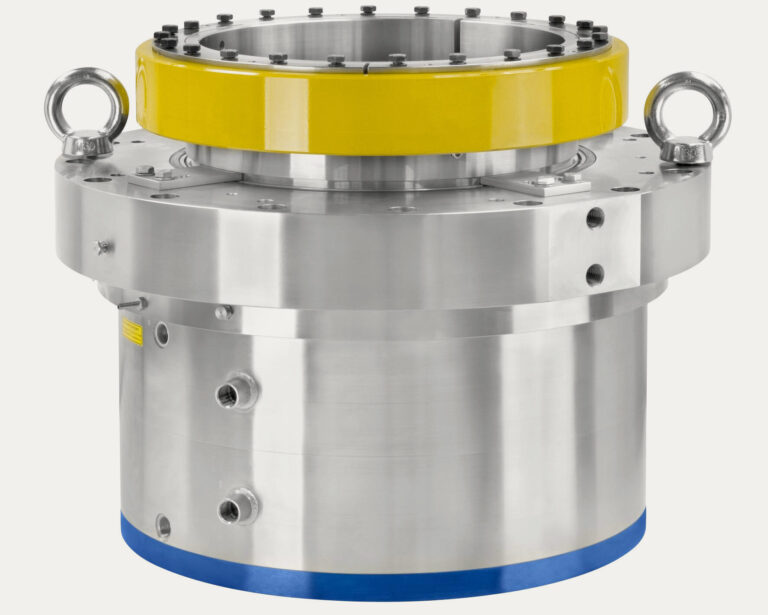

High Pressure Seal ESD64H

Function and application

- Double-acting mechanical seal liquid lubricated for high pressure applications

- Robust high pressure seal with four geometrically identical seal rings arranged back-to-back

- Position of the seal rings remains unchanged, even when the pressure is reversed

- Application in high pressure processes including supply systems - Maximum requirements for reliability

- Suitable for frequent changes in pressure, extremely high temperatures and significant agitator shaft displacements

Advantages

- Resistant to pressure changes

- Resistant to agitator shaft displacements

- No deformation of the mechanical seal under pressure

- High temperatures possible / better heat dissipation

- Minimal leakage

- Extended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life timeExtended life time

Working limits

- Operating pressure: vacuum...100 bar (abs.)

- Vessel temperature: -50...+400°C

- Shaft size: 40...220 mm

- Sliding speed: 0...3 m/s

The EKATO ESD64H is most suitable for

- Bulk chemicals

- Specialty chemicals

- Hydrometallurgy

Liquid Lubricated ESD64G

Function and application

- Double-acting, liquid lubricated mechanical seal

- Four geometrically identical, mounted mechanical seal rings

- Ideal mechanical seal for large diameters in the medium pressure range up to 40 bar (abs.)

- Available with short heat trap for cooling

- Optionally with water jacket

Advantages

- Robust against pressure change

- Robust against shaft deflection

- No mechanical seal deformation under pressure

- Good heat dissipation

- Minimal leakage

Working limits

- Vessel pressure: vacuum...40 bar (abs.)

- Vessel temperature: -50...400°C

- Shaft diameter: 240...500 mm

- Sliding speed: 0...5m/s

The EKATO ESD64G is most suitable for

- Bulk chemicals

- Polymers

- Specialty chemicals

- Sterile processes

- Hydrometallurgy

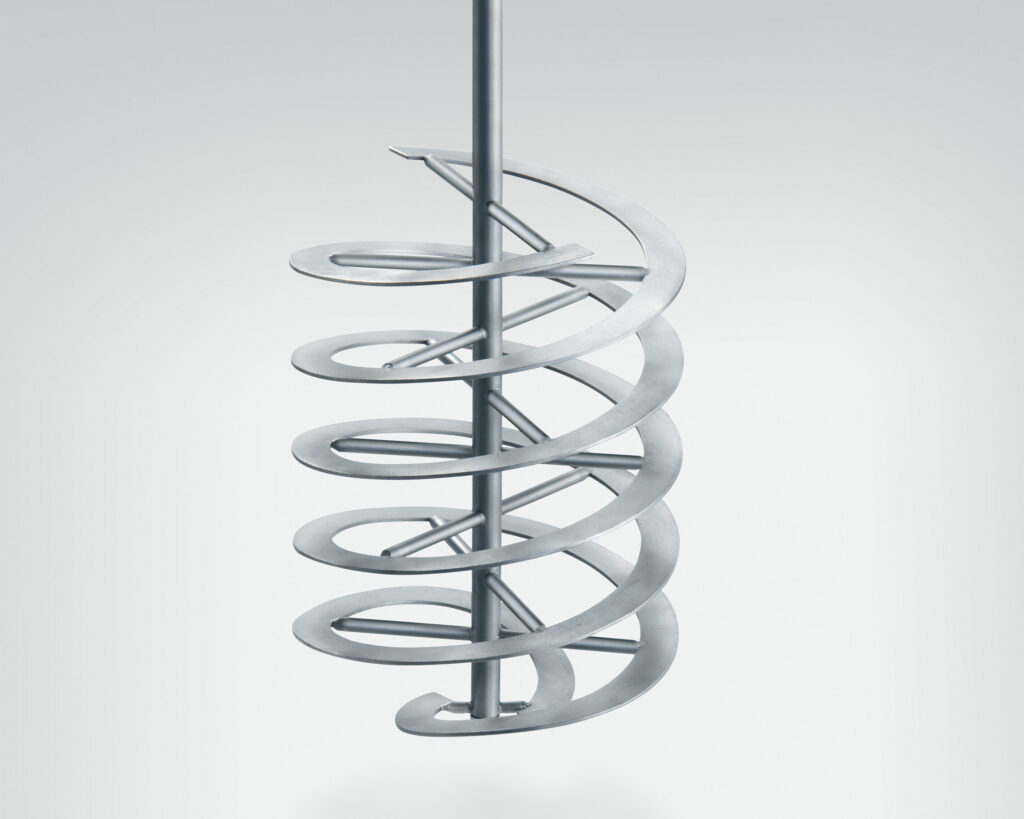

Product Lubricated Mechanical Seal ESD44

Function and application

- Double-acting mechanical seal liquid lubricated for slurry applications

- Pair of product side seal rings extends into the vessel space

- Surfaces are smooth and the design minimizes gaps to prevent dirty corners - thorough cleaning is possible

- Sealing abrasive suspensions and sticky or crusty media (below liquid level, side entry installation)

- Sterile seal construction (ESD44S) also available - any orientation possible

Advantages

- No dirty corners, thorough cleaning possible

- Can be sterilized

- Solid design

Working limits

- Operating pressure: vacuum...16 bar (abs.)

- Vessel temperature: -50...+230 °C

- Shaft size: 40...300 mm

- Sliding speed: 0...5 m/s

The EKATO ESD 44 is most suitable for

- Specialty chemicals

- Formulated consumer products

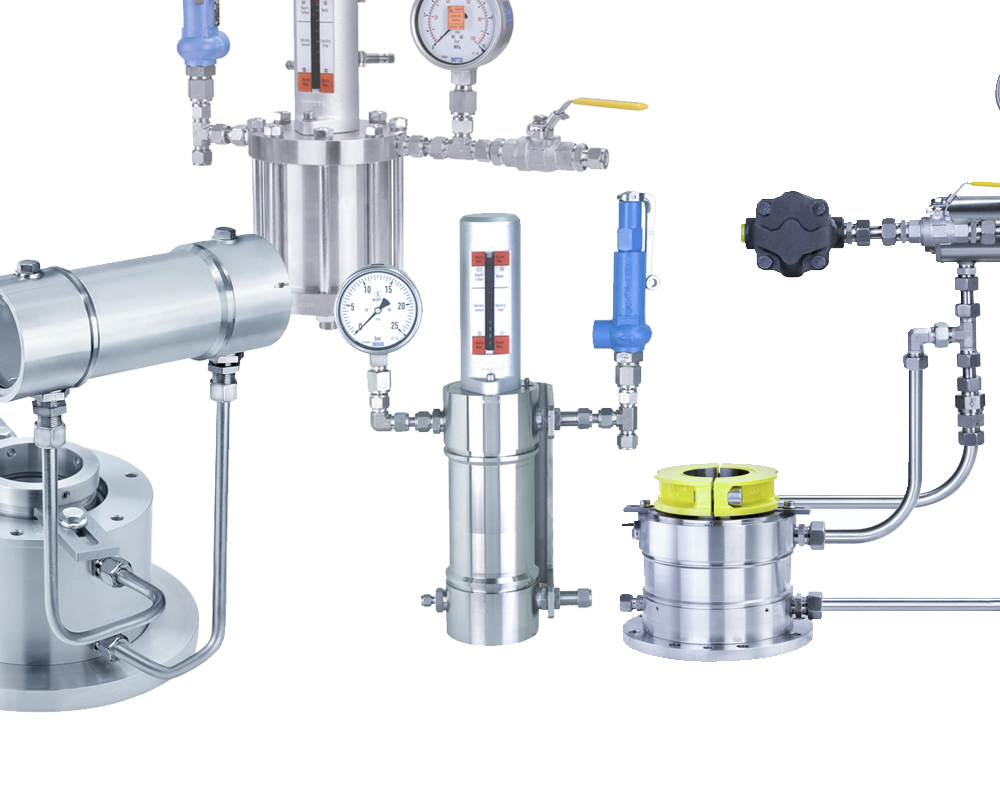

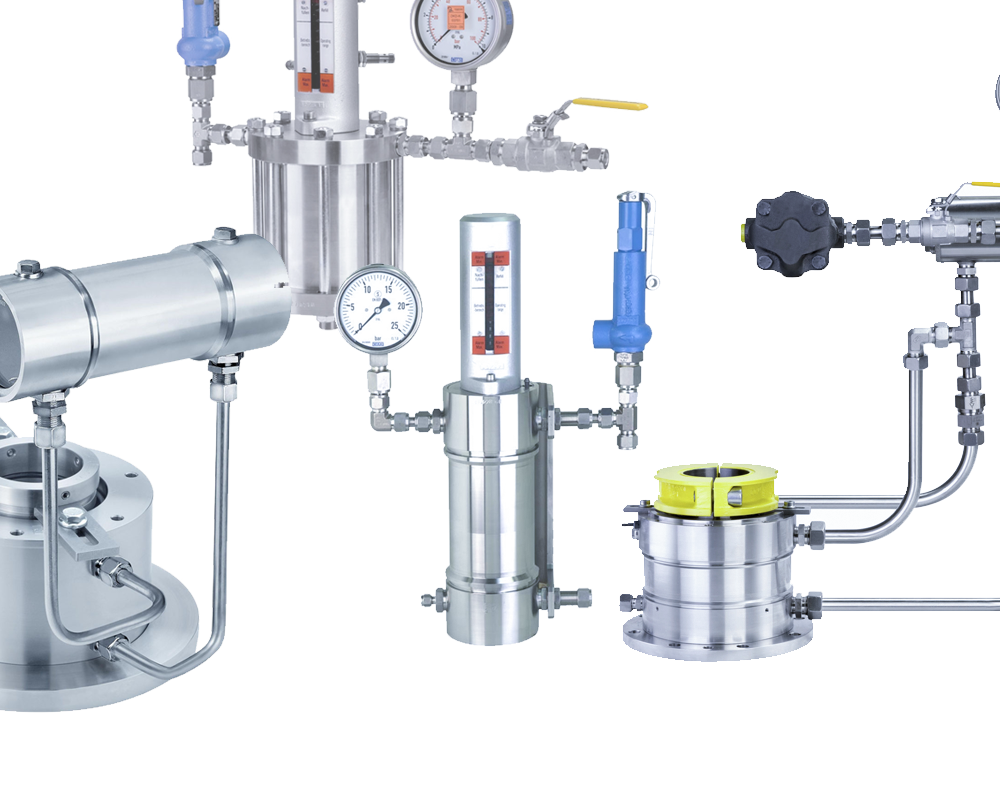

Sterile Seal ESD34/44S

Function and application

- Ideal for sterile processes

- Delivered in a complete sterile system including sterile installation

- Seal liquid condensate cooled by a plate heat exchanger

- Continuous sterilisation of the condensate by fresh steam

Advantages

- Complete sterile system, mechanical seals and sterile installation from a single source

- Ready-to-install cartridge unit

- No gaps: ideal for sterile processes

- ESD sterile installation operates virtually maintenance-free and consumes very little energy

Working limits

- Operating pressure: vacuum...4.5 bar (abs.)

- Steam temperature: 130°...150°C

- Shaft size: 40...300 mm

- Sliding speed: 0...5 m/s

The EKATO ESD ESD34/44S is most suitable for

- Specialty chemicals

- Pharmaceutical products and cosmetics

- Biofuels and bio refineries

High Speed Mechanical Seal ESD114

Function and application

- Double acting mechanical seal liquid lubricated

- Used for products with a high solids content and sterile processes

- Perfect for high-speed shafts

Advantages

- Easy to clean and sterilize

- Extended life time, even on high-speed machines

Working limits

- Operating pressure:vacuum...6 bar (abs.)

- Vessel temperature: -20...+200°C

- Shaft size: 40...220 mm

- Sliding speed: 0...20 m/s

The EKATO ESD ESD114 is most suitable for

- Formulated consumer products

- Pharmaceutical products and cosmetics