EKATO

SOLIDFOIL

Perfect Handling of Continuously Flowing Solids

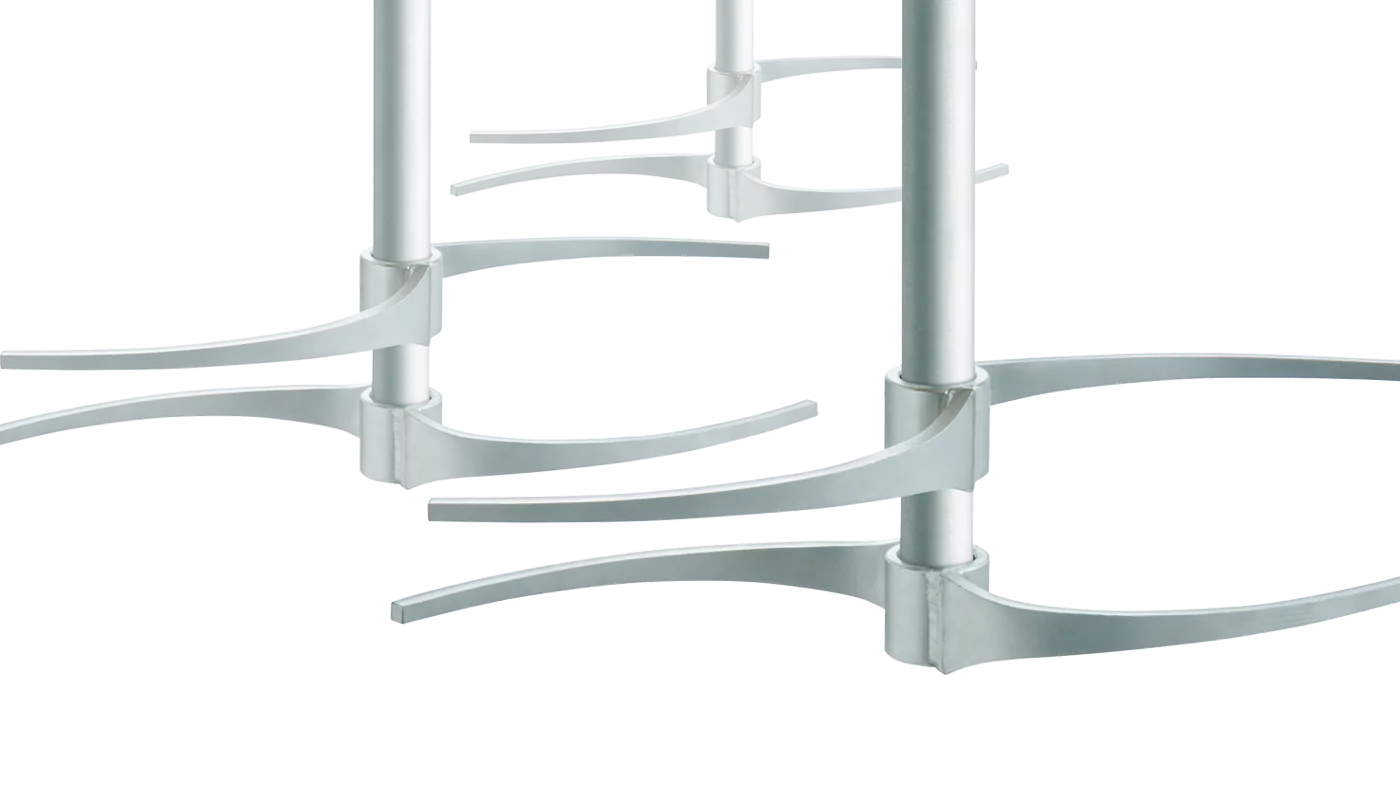

An impeller for continuous mixing or handling of bulk materials which avoids clumping of adhesive bulk materials and intensifies the surface contact between solid and fed gas through surface renewal.

Agitators are normally used during continuous mixing or handling of bulk materials. One the one hand, this is important to allow a mixing process. On the other hand, mixing avoids clumping of adhesive bulk materials or intensifies the surface contact between solid and fed gas (surface renewal) , for example, when stripping monomer residues from polymers. To serve this application, EKATO developed the EKATO SOLIDFOIL as a result of extensive trials in our own laboratory. This impeller is normally applied as a multi-stage mixing system. The unique blade profile diverts the solids axial flow through the vessel into a radial alternate outward and inward direction. As a result, a narrow residence time distribution in the entire vessel occurs, leading to an uniform process result and a better product quality. Simultaneously, the bulk material is permanently restructured which avoids clumping, continuously offering new surfaces for desorption processes for example.

Features

- Uniform process results due to narrow residence time distribution in equipment with vertical flow

- Optimized blade profile that conveys the solids alternately outwards and inwards in a radial direction

- The curvature and adapted height of the blade generates a constant volumetric flow rate along the blade

- The blade geometry can be adapted to the wall friction angle of the product