PARAVISC

The Flexible Multi-Purpose Impeller, Ideal for Highly Viscous Products

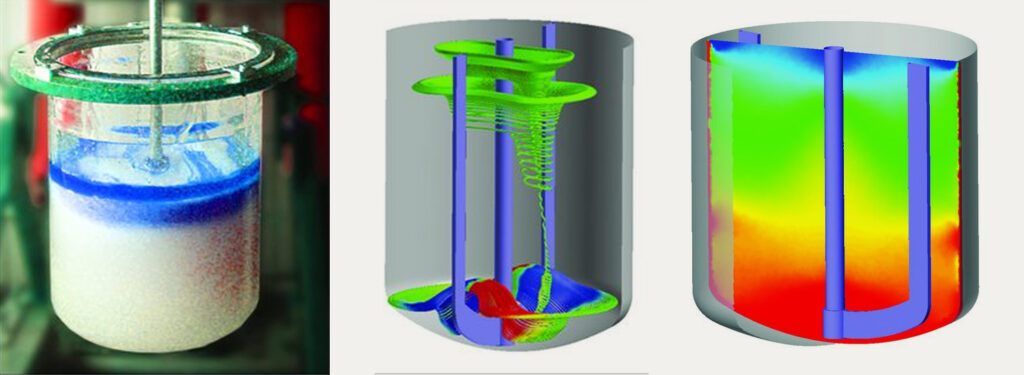

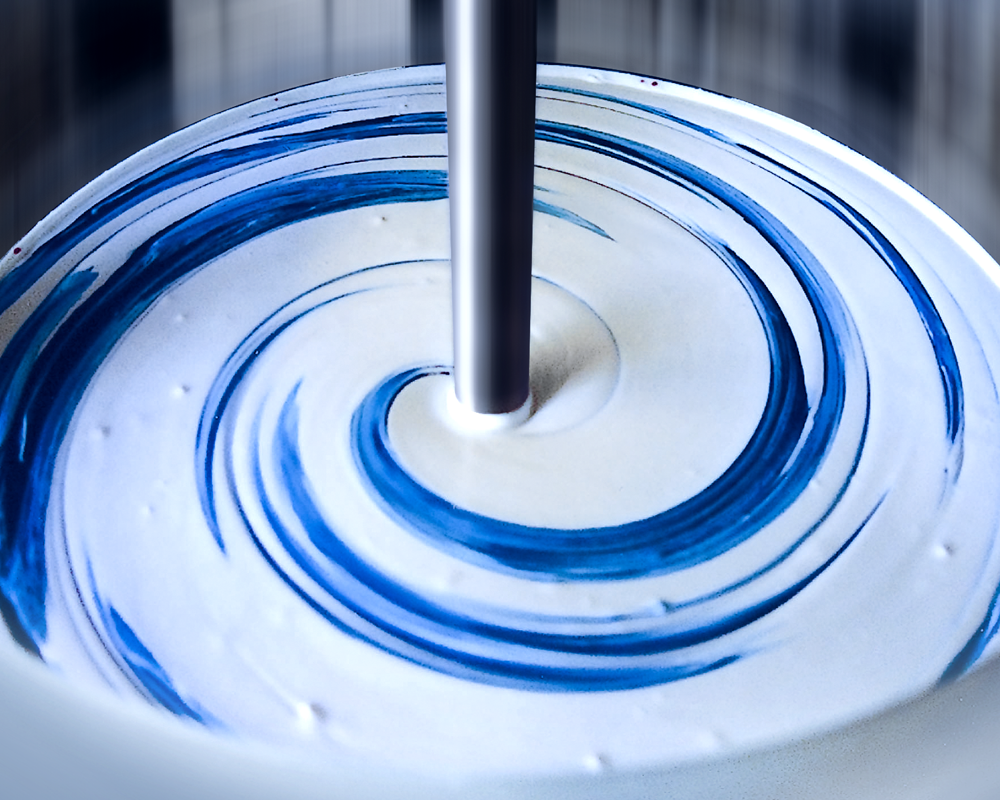

EKATO PARAVISC Impeller for highly viscous mixing (in comparison to Anchor)

Video

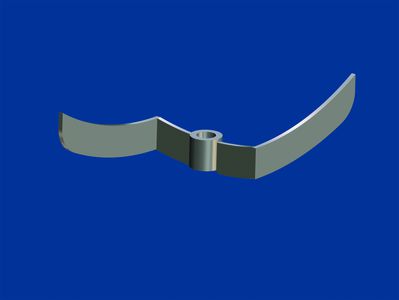

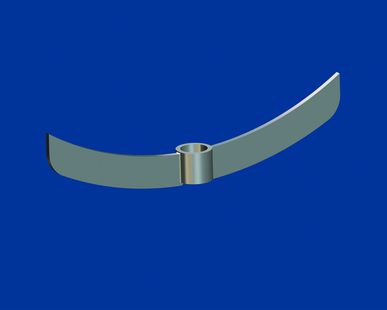

EKATO PARAVISC in comparison to Comb Blade EKATO technology vs. regular blades

Typical Applications

- Cosmetics (creams, lotions, gels)

- Tooth paste

- Silicones

- Silicone rubbers

- Latex and polymers

- Paints and lacquers

- Epoxy resins

- Adhesives

- Hot melts

- Sealing compounds

- Insulating materials

- Building materials

Reduces the Mixing Time up to 50% and Increases the Homogeniety

By using an optimized flow profile, the raw materials are homogenized within the shortest time even at high viscosities. Not only reduced batch times and an increased throughput can be achieved, but a further increase in product quality is possible. A further process improvement can be achieved by applying the coaxial system.

Improves the Temperature Distribution when Heating and Cooling

Installing baffles avoids scaling – a more homogeneous temperature distribution is achieved. Heat transfer and homogenization are markedly improved and scaling on the vessel wall is mitigated.

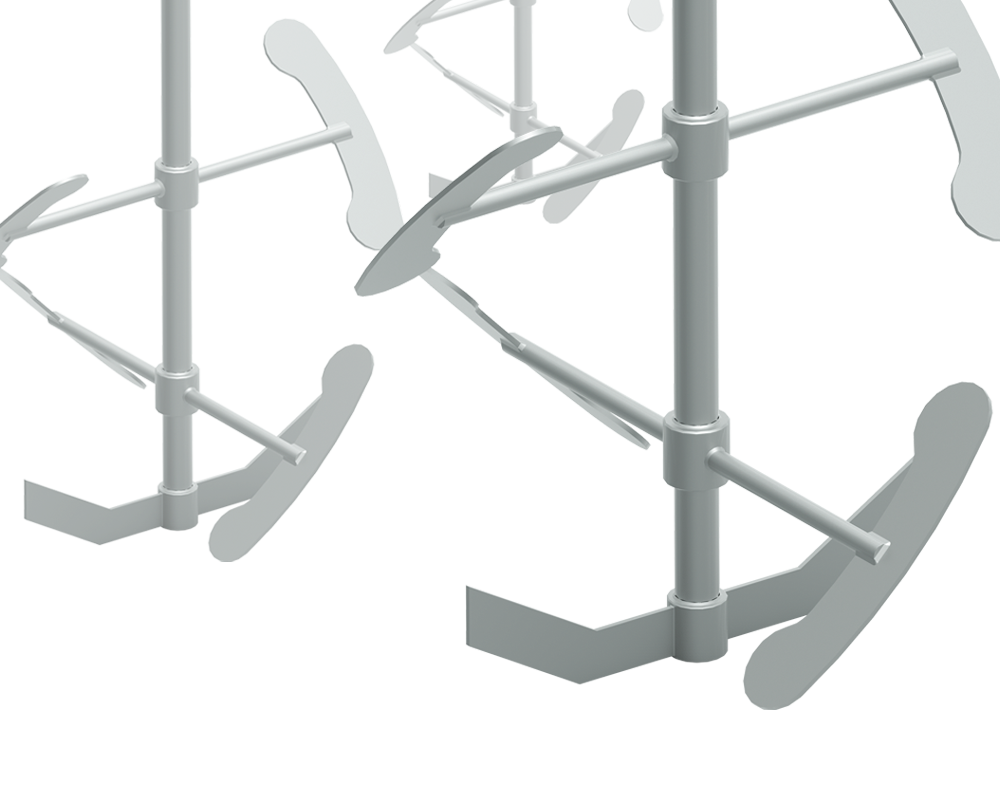

Modular System

The modular EKATO PARAVISC system allows a flexible response to rheological properties and product requirements. This provides a variety of designs which in each case are especially suitable for certain applications.

Design Advantages

- System adapted to the given process requirements Blending, dispersion and heat transfer up to 1,000,000 mPa s

- Broad range of products can be handled in one vessel

- Separate process steps can be performed in one vessel

- Minimization of product residue due to steep blade angle

- No stagnant areas

- Can be retrofitted

- Bolted or welded versions

- Wide range of products