Plastics

Polymer Production and Chemical Polymer Recycling

Advanced plastics recycling, also called chemical recycling, refers to several different technologies that convert used plastics into their original building blocks, specialty polymers, feedstocks for new plastics, fuels, waxes, and other valuable products.

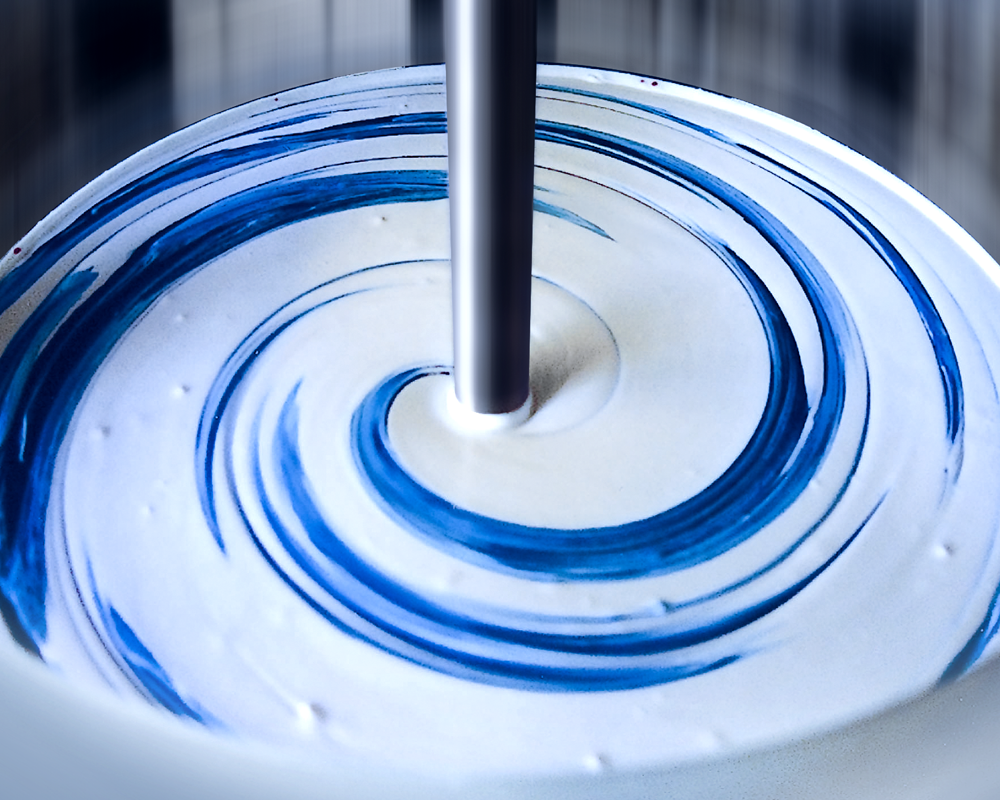

EKATO’s Technology Center provides the maximum flexibility to develop and optimize agitation systems applied in polymer recycling. We welcome you to check the potential of new impeller types, components and reactor systems thus guaranteeing tested quality levels. Along with developing solutions, EKATO’s main focus is on analysing the impact of operating modes, raw materials and energy savings and comparing different machine and process concepts. The use of modern simulation methods complements the trials and helps to find the best settings in a cost-effective way.