Petrochemical

Agitators for Storage Tanks (Crude and Refined Oil)

Oil Keeps the World Moving

…and EKATO is at the mix in terms of mobility, heat, petrochemicals, lubricants and bitumen.

In oil storage tanks, EKATO relies on proven technology and can build on more than 85 years of experience. On request, the design can also be confirmed by CFD (Computational Fluid Dynamics) numerical flow simulation.

For mixing tasks like effective mixing of crude oil considering and controlling the sand and water content, BS&W (bottom sludge and water / base sediment and water), mixing of different crude oils, a constant temperature distribution in the tank or for the mixing of refined oils, EKATO provides the appropriate solutions.

Portfolio

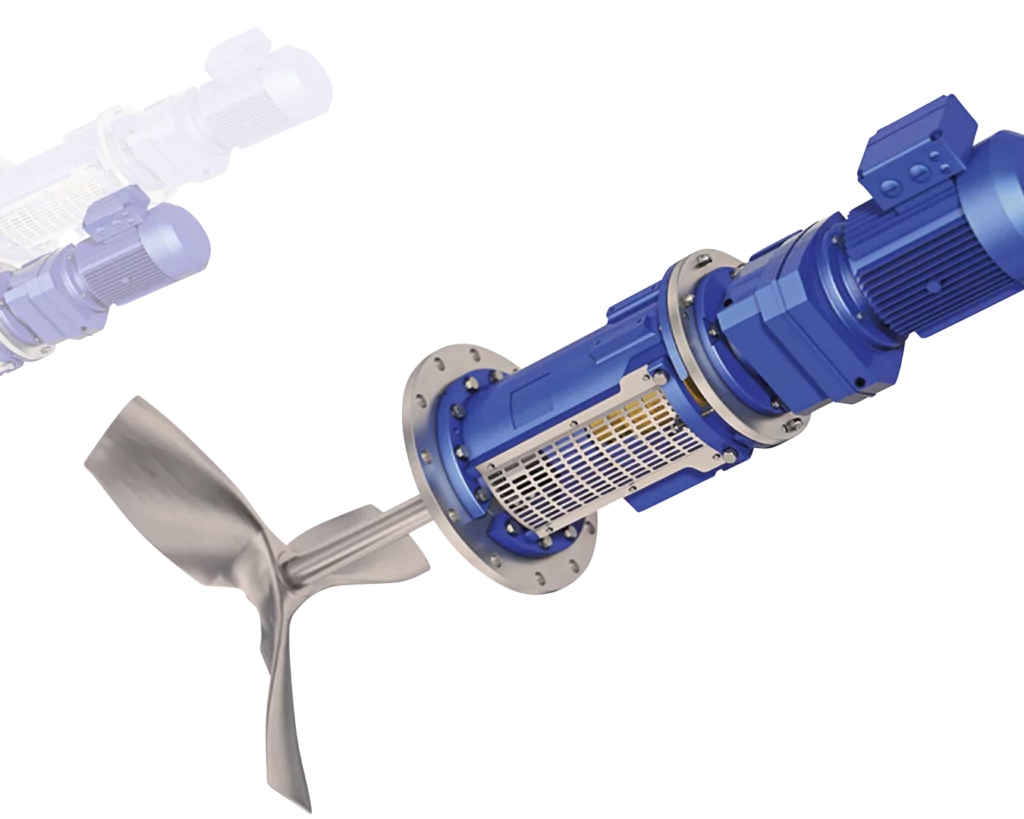

EKATO Side-Entry Agitator ES 2000 SW

The swiveling EKATO side-entry agitator for crude oil storage tanks is a compact, state-of-the-art technology. It uses a single or double mechanical seal system according to API 682, modified for agitators. It represents a reliable solution for the oil and petrochemical industry. Manual adjustment on site or automatic positioning in the process control system (PCS) are available options to swivel the agitator.

The decisive factors for trouble-free operation of the agitators are:

- Optimal alignment at the vessel wall

- Impeller stream length

- Pumping capacity of the impeller

Our operational experience in the field of side-entry agitators, together with computational fluid dynamics (CFD) simulations, allows us to determine the optimum number and orientation of agitators around the tank circumference. Reliable, easy-to-maintain, and economical operation are the main benefits based on our knowledge and know-how of side-entry agitators.

可转角齿形皮带设计

- 抗静电高扭矩驱动(HTD)齿形带

- 带强制锁定(夹紧法兰)的关闭装置,用于维护或更换满罐容器的密封件,最大 7 巴(绝对)

- 集装式设计的 EKATO 机械密封,针对搅拌器进行了改进

- 旋转装置,手动或自动调节

- 高效桨叶 (EKATO 推进式桨叶)

- 接触液体产品不锈钢材料,符合 NACE

| 电机功率 | 7,5 - 55 kW |

| 轴径 | 60 - 100 mm |

| 操作压力 | 常压 - 液柱压力 |

| 认证 | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 认证 |

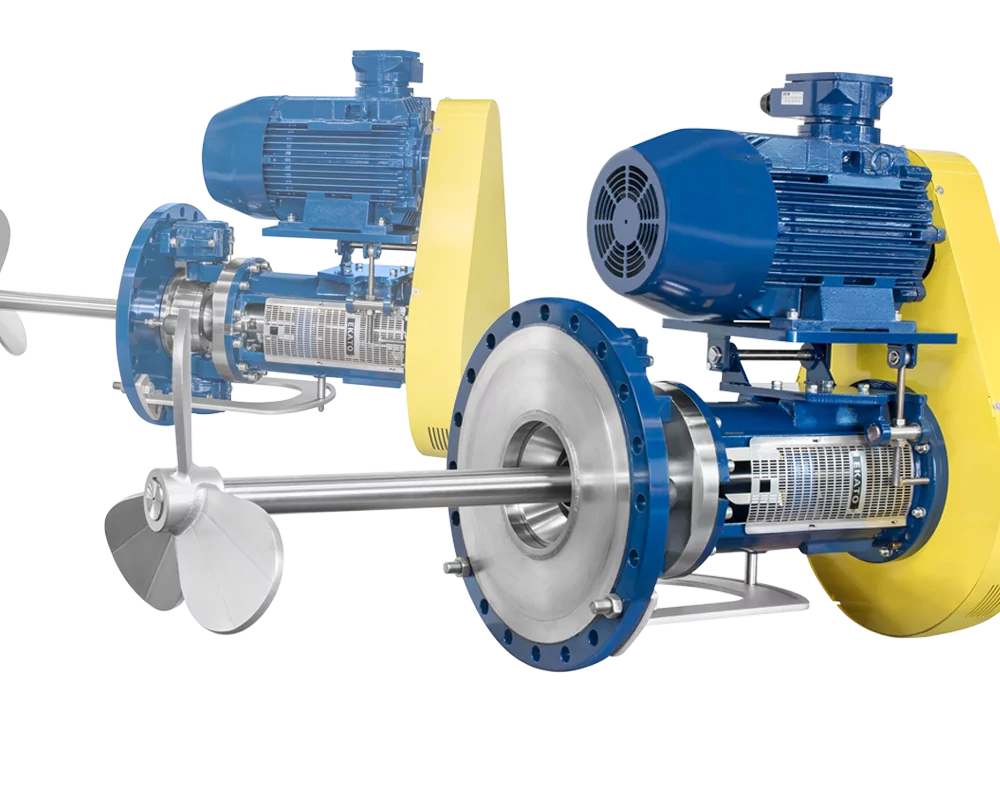

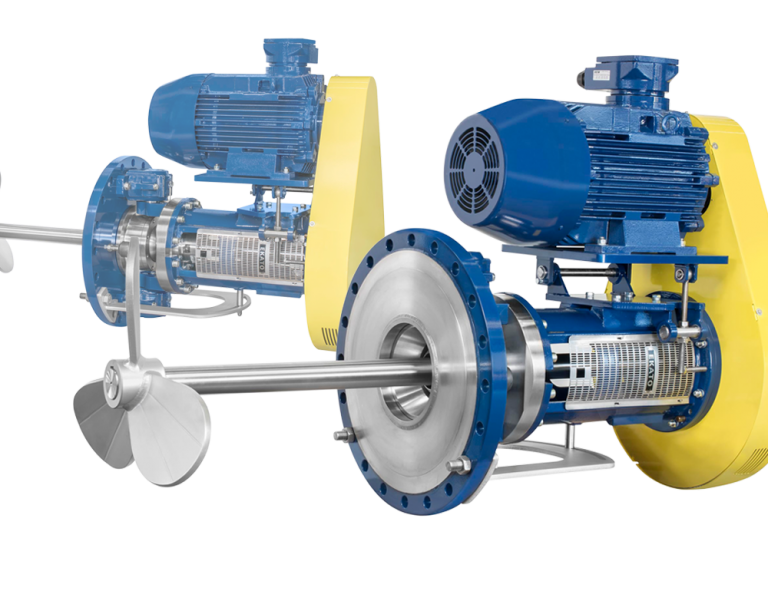

EKATO Side-Entry Agitator ES 2000 / ES 2000 Z

Fixed toothed belt design

- Antistatic high torque drive (HTD) toothed belt

- Shut-off device with positive locking (clamping flange), for maintenance or seal replacement with filled vessel, max. 7 bar (abs.)

- EKATO mechanical seal in cartridge design, modified for agitators

- Optionally with adapter flange design

- High efficiency impeller (EKATO propeller)

- 接触液体产品不锈钢材料,符合 NACE

| Motor Power | 7,5 - 55 kW |

| Shaft Diameter | 60 - 100 mm |

| Operating Pressure | Atmospheric - liquid column |

| Approval | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 approval |

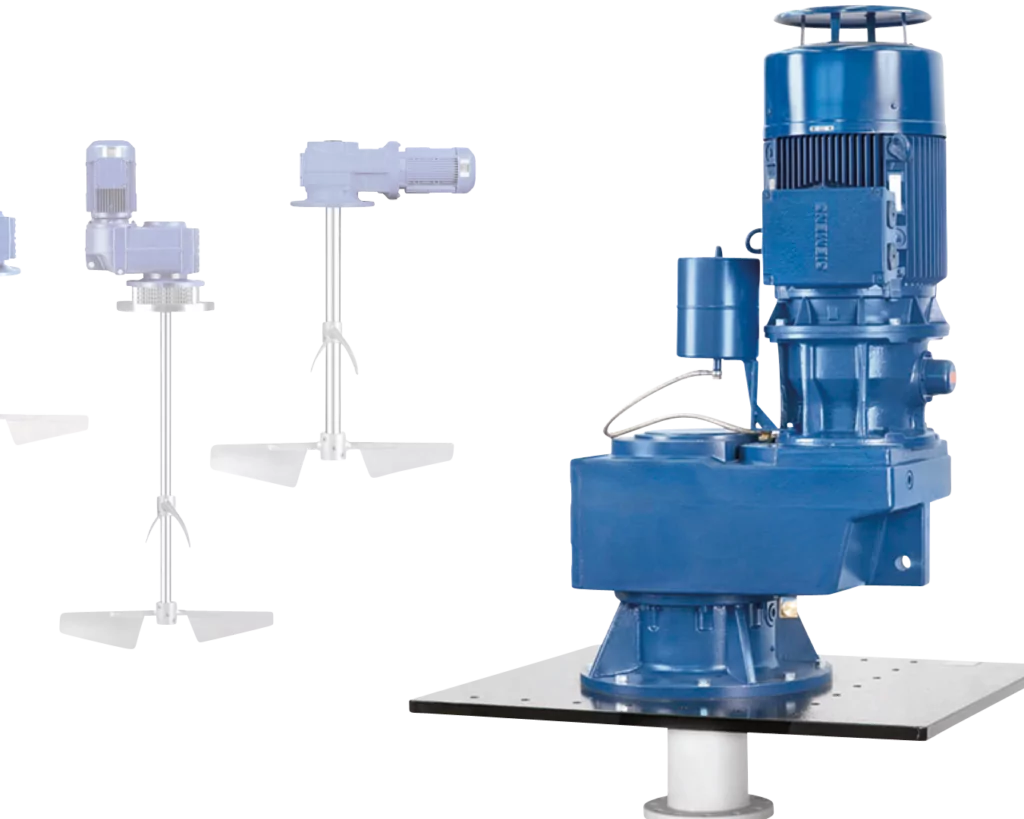

固定齿轮箱设计 ES 2000

带齿轮箱的设计适用于 3 – 22 kW 的电机功率范围和更大直径的搅拌器。

搅拌机设计

- 电机带各种齿轮箱

- Shut-off device with positive locking (clamping flange), for maintenance or seal replacement with filled vessel, max. 7 bar (abs.)

- EKATO mechanical seal in cartridge design according to API 682 publications, modified for agitators

- 可选配适配法兰设计

- 高效桨叶 (EKATO propeller)

- 接触液体产品不锈钢材料,符合 NACE

| Motor Power | 3 - 22 kW |

| Shaft Diameter | 40 - 80 mm |

| Operating Pressure | Atmospheric - liquid column |

| Approval | ATEX 2014/34/EU, EAC TR-ZU 010/012-2011 approval |

R&D 测试容器

With our new test tank with a tank diameter of 3.2 m, a height of 1.74 m and a total volume of 14 m³, an improved scale-up to operating scale has been realized. Up to 10 side-entry agitators can be operated, and the behavior of crude oil can be investigated in depth. Optionally, the scale-up design can be confirmed with a CFD analysis.