Mixing Technology for the Food Production Industry

Mixing Technology for Hydrogenation and Fermentation

Challenges in the Food Production Industry

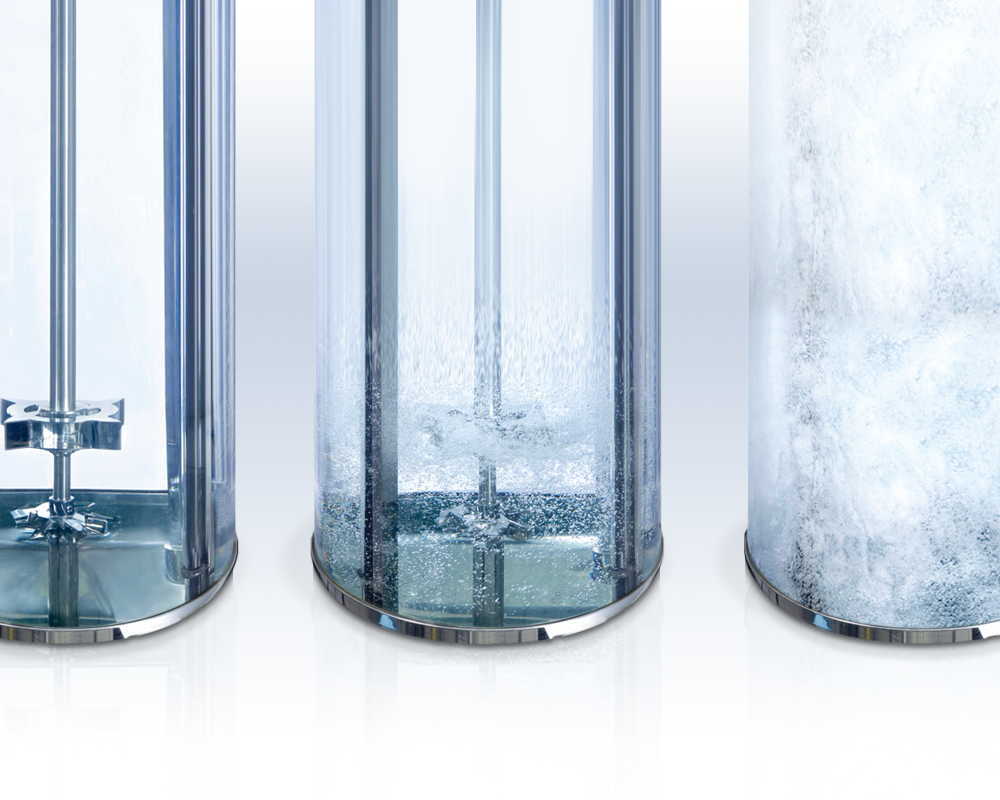

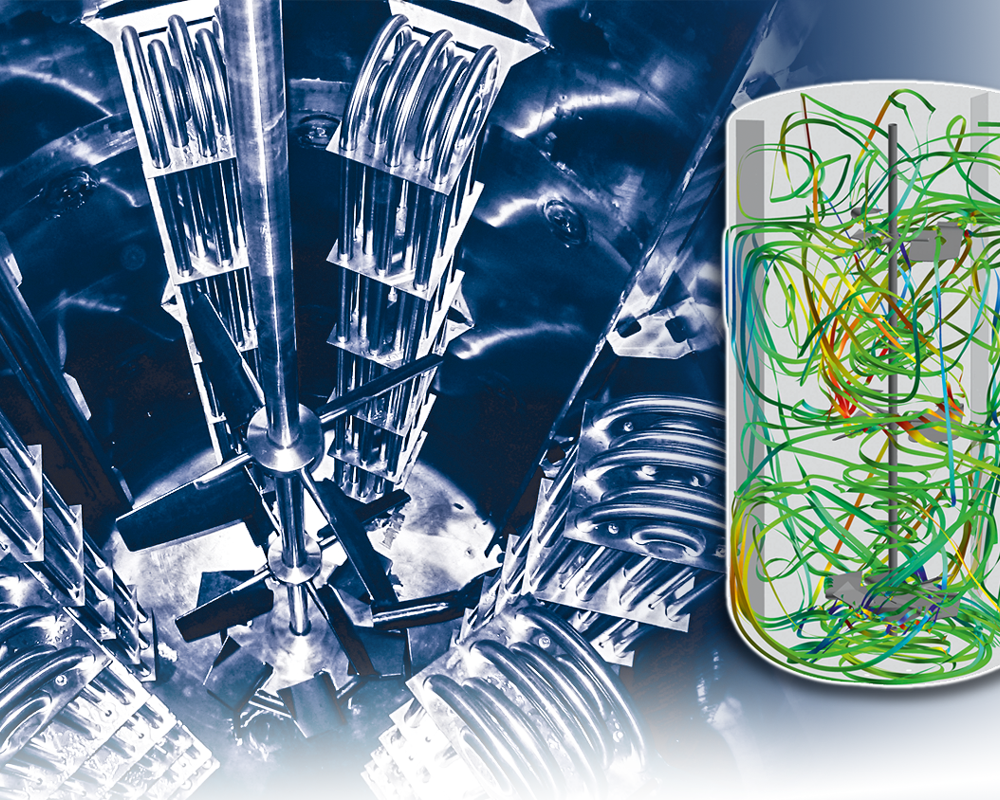

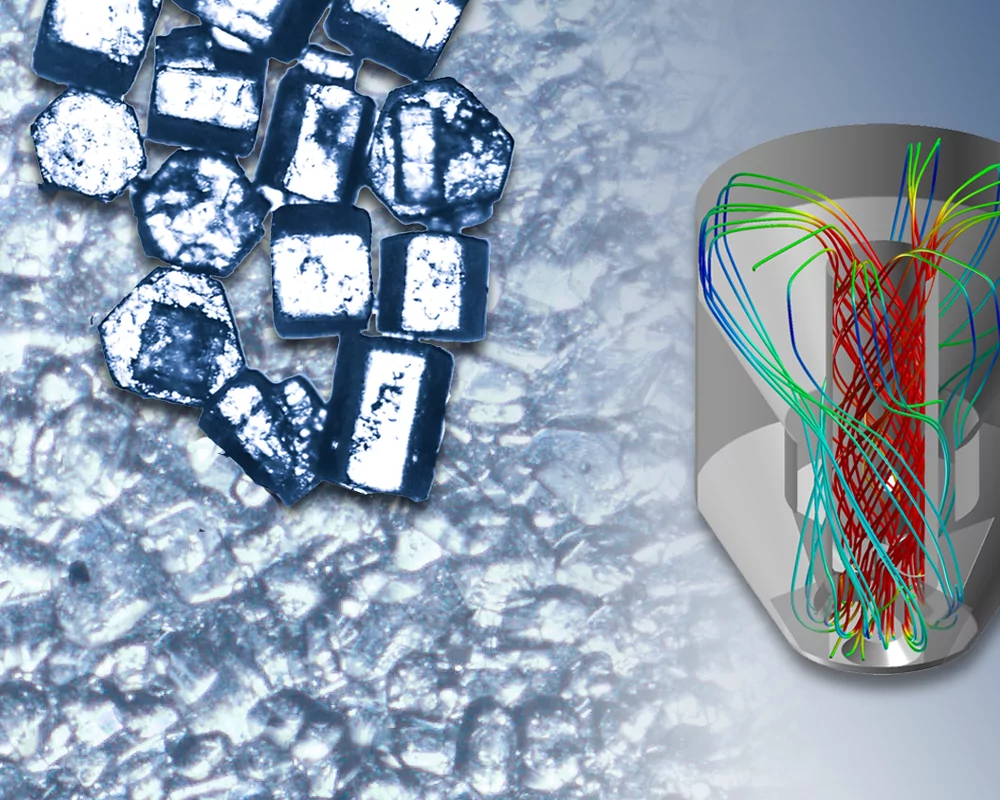

During crystallization, yield, purity, and, most importantly, the particle properties determine the quality of the end product. Especially in cases where additives or sugar substitutes are used, the process can be significantly enhanced and made more efficient by using the right agitation technology and crystallization strategy. Many substitutes of sugar like Sorbitol and Xylitol are produced by hydrogenating the appropriate sugar. By using state-of-the art mixing technology (e.g. the EKATO Combined Gassing system) the space-time yield can be increased significantly while the catalyst amount can even be reduced.

The EKATO Combined Gassing system doesn’t only offer advantages to the production of sugar substitutes, but also to the production of hydrogenated fats, e.g. margarine. In this case the EKATO Combined Gassing system can significantly reduce the time to reach the required iodine number, thanks to its excellent mass transfer. Whether its stirring, blending, dissolving, heating, cooling, fermentation or hydrogenation – the EKATO agitator is your main support to reach the desired product quality and characteristics.

Typical Products Made in the Food Production Industry:

- Fats

- Sugar

- Sugar substitutes

- Dairy products

- Juices

- Concentrates