Mixing Technology in the Biotech Industry

Fermentation, Homogenization, and Sterilization Processes

Fermentation and Biotech

EKATO supports companies in the biotech field in four areas, which include biotechnological processes such as fermentation, homogenization, and sterilization, as well as the synthesis of bio-based and biodegradable basic materials. EKATO’s expertise is based on decades of experience with fermentation processes, the planning, analysis, and implementation of lab tests, as well as the ramp-up to industrial-scale volumes. In addition, the company has completed numerous (reference) projects in and around the production of sugars and sugar substitutes as well as the synthesis of green chemicals and polymers.

One of the tasks of fermentation is to synthesize chemical compounds by using enzymes, bacteria, fungi or yeasts. New applications have been made possible due to recent advances and new insights in many fields of biotechnology, for example the function of micro-organisms in the microbiology, improvements in sterilization and cultivation of cells, as well as targeted genetic manipulation to produce high-performance organisms. Needless to say, mixing technology has made a substantial contribution. Modern fermentation processes are used to obtain substances such as enzymes, active pharmaceutical ingredients, amino acids and vitamins as metabolites from micro-organisms. Many of these production processes are carried out most effectively in agitated fermenters.

Manufacturing processes that are both environmentally sound and climate friendly are becoming far more important in the process industry. Agitation reactors are commonly used in the production of bio-based and biodegradable chemicals and polymers. In processes like this, the targeted use of customized agitator systems helps ensure efficient mass and heat transfer, making a major contribution to the sustainability and environmental friendliness of the processes.

Process Requirements & Challenges

In fermentation processes, the development is facing increases in productivity and maximum fermenter volumes (economies of scale). The production of secondary metabolites can also result in fermentation broths with very high viscosities and extreme, non-newtonian behavior.

Consequently, the challenges for the fermenter in combination with the agitator system are rising with respect to homogenization of the fermentation broth, heat transfer and air dispersion. In order to achieve a successful scale-up from lab into production scale, EKATO offers its comprehensive know-how.

EKATO's Know-how

Ideally, the collaboration already starts in the phase of lab-scale tests. In this case, EKATO can also assist in planning tests and analyzing the results, in order to get the necessary information for an optimal scale-up of both process and geometrical parameters.

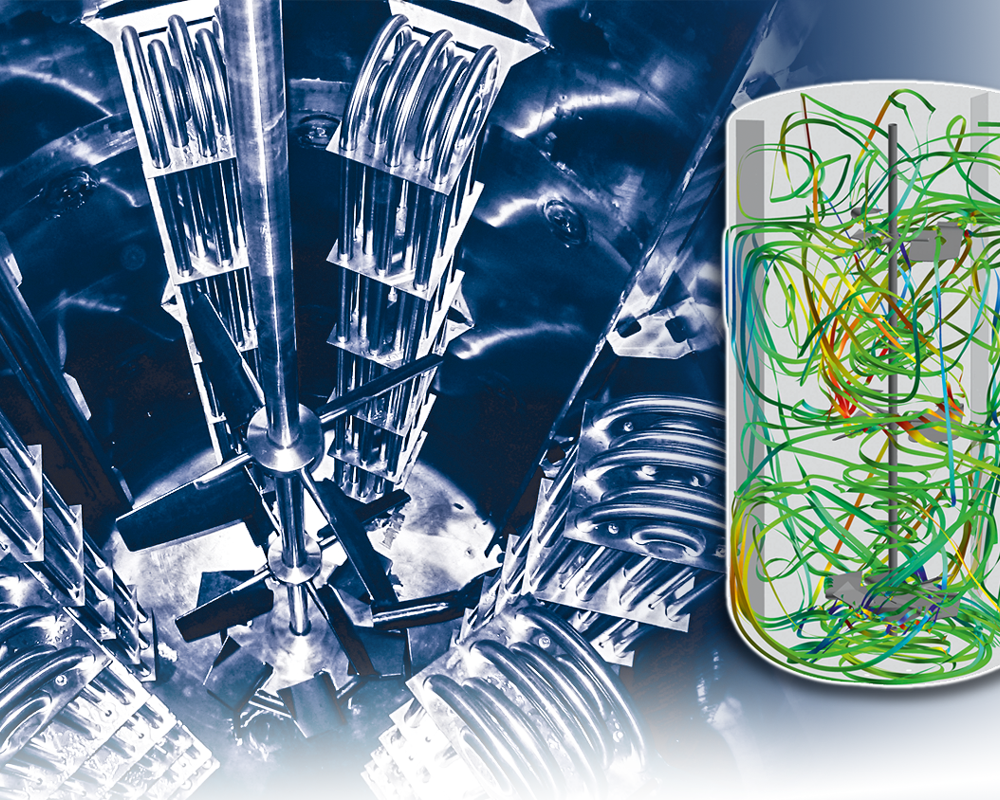

The choice of the agitator system and the fermenter geometry, together with the heat transfer elements and baffles, can be accompanied by a numerical flow simulation (CFD). In order to enable a safe and failure-free operation of all fermenter components, the mechanical scale up can be assured by a Finite Element Analysis (FEA).

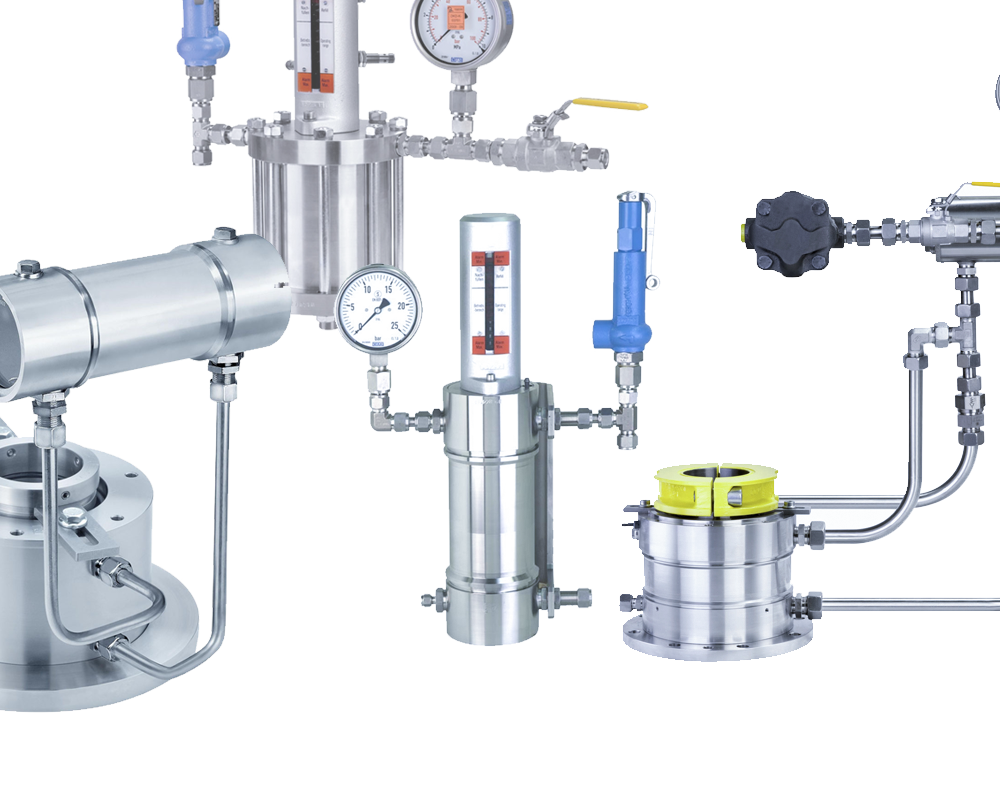

In case of special demands for sterile design, EKATO offers the solution for the fermenter internals but also special sterile designs for sealing systems.

Applications:

- Bio-based and biodegradable products

- Fermentation

- Green Chemistry

- Green Polymers