EKATO

Side-Entry Agitator HWL for Flue Gas Desulfurization

Proven Reliability - World's Much Sold FGD Agitator

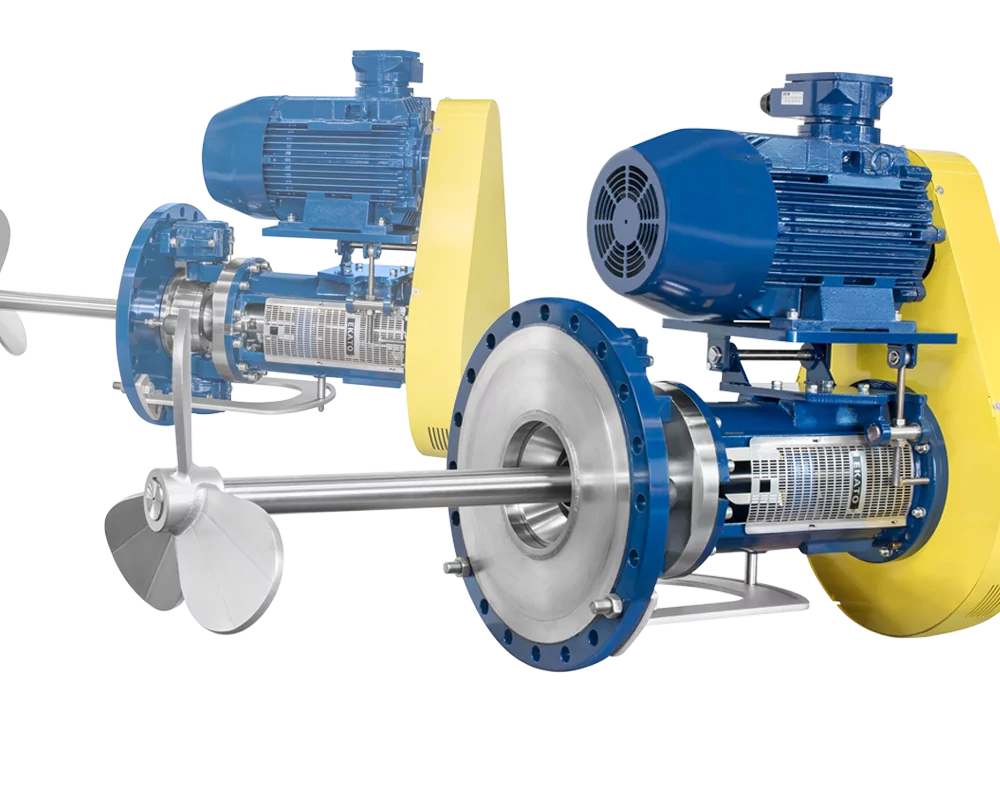

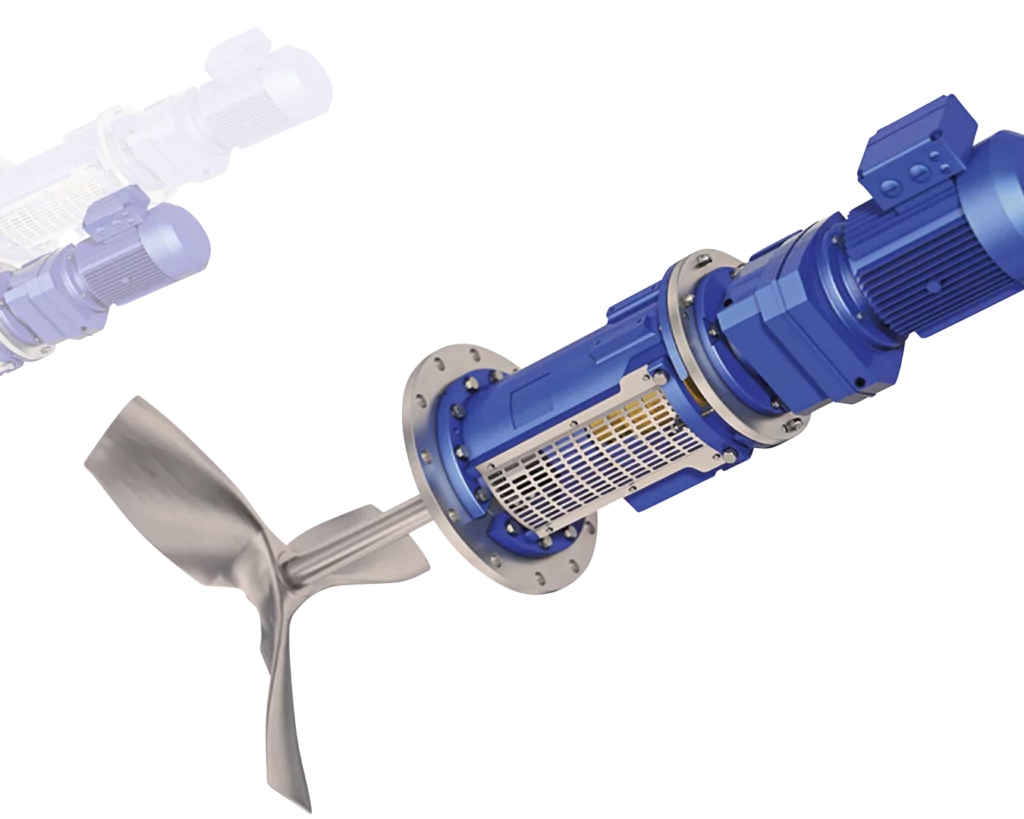

The EKATO HWL FGD Side-Entry agitator was specially designed to be used in absorber towers of flue gas desulfurization plants. The agitators are designed and manufactured for fatigue strength, based on rated motor power and maximum dynamic loads. The HWL-FGD side-entry is the world’s most-sold side-entry agitator for absorber towers in flue gas desulfurization plants. The reliability of these extremely robust agitators is proved by over 1,500 FGD-plants.

Key facts

| Motor Power | 3 - 90 kW |

| Shaft Diameter | 40 - 120 mm |

| Operating Pressure | Atmospheric - 7 bar |

| Impeller-Systems | WINGJET, Propeller |

| Materials (product wetted) | Rust- & acid resistant steels, nickel-base alloy, Duplex- & Super Duplex steels |

Design Features

- Drive versions from 3 – 90 kW with different gearbox types (V-belt drive, helical-, bevel gearbox..)

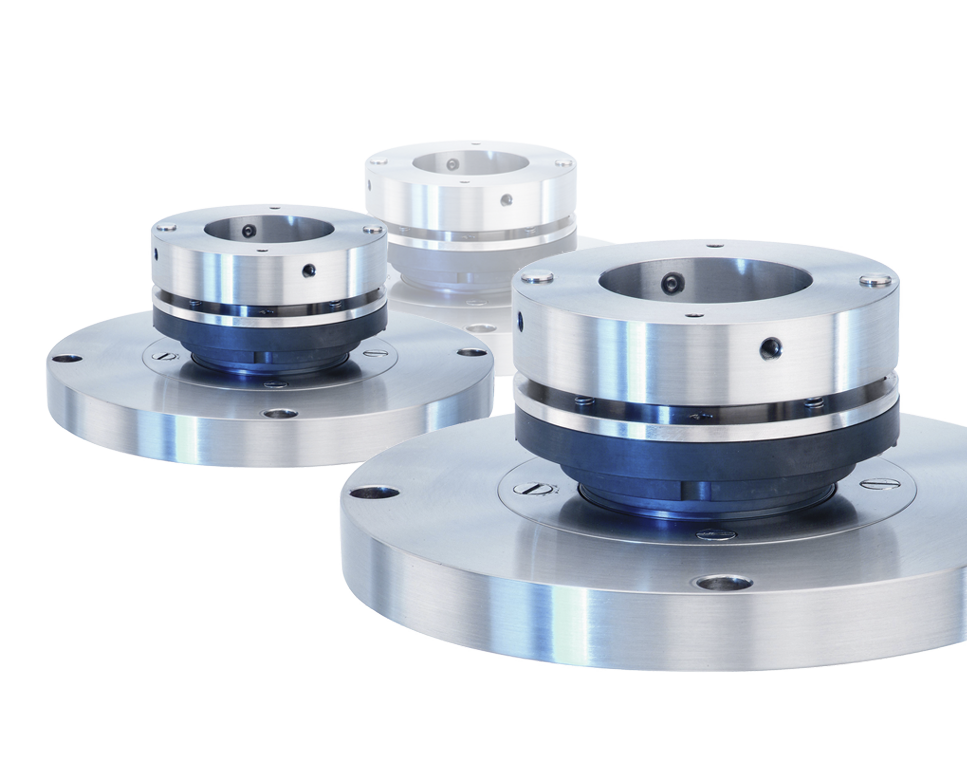

- Mechanical Seal EKATO 42L: Single acting product lubricated mechanical seal for the FGD side- entry agitators. This cartridge type mechanical seal is specifically designed for highly abrasive and corrosive media.

- Shut-Off device: The shut-off device makes it possible to service the mechanical seal, or even replace it entirely, without shutting down or emptying the absorber tower.

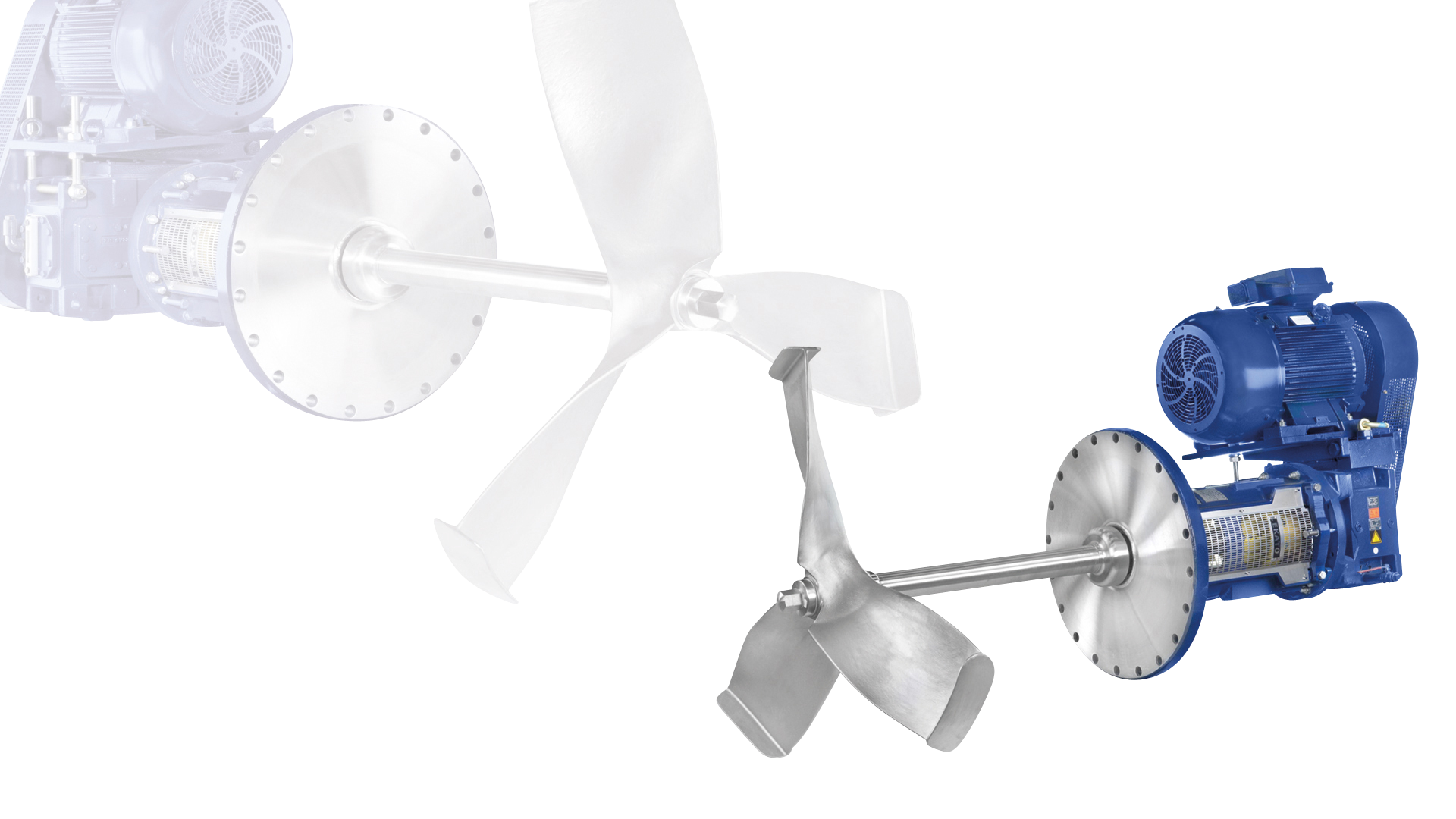

- EKATO Wingjet impeller: Specifically developed for the use in absorbers for flue gas desulfurization. With its CFD optimized geometry and its cast formed blades this impeller offers the following advantages:

- The impeller is constructed of highly corrosive and abrasive resistant Super Duplex materials.

- Available diameters: 800 - 2000 mm

- Optimized efficiency

- Bundled axial flow

- Increased pumping capacity

- Winglets suppressing the tip vortex for reduced impact corrosion, longer operational life and reduced maintenance costs

EKATO Side Entry Agitatorsfor FGD absorbers

Additional Features

- EKATO WINGJET with hollow mixer (WINGJET O2) for dispersing particularly high amounts of gas