EKATO

Coaxial Agitators KOAX

High Performance - For Complex Processes and Extreme Viscosities

EKATO coaxial agitators are high performance units equipped with two universal impeller systems, each with an independent drive system. All kinds of mixing tasks arising in the different process steps such as homogenizing, suspending, dispersing, heat transfer as well as the decomposition of solids, can be combined and performed. This mixing system is preferred for complex mixing processes and products with extreme viscosities and flow behaviors.

Key facts

| Motor Power | 5 - 250 kW |

| Shaft Diameter | 40 – 220 mm |

| Operating Pressure | Vacuum - 40 bar |

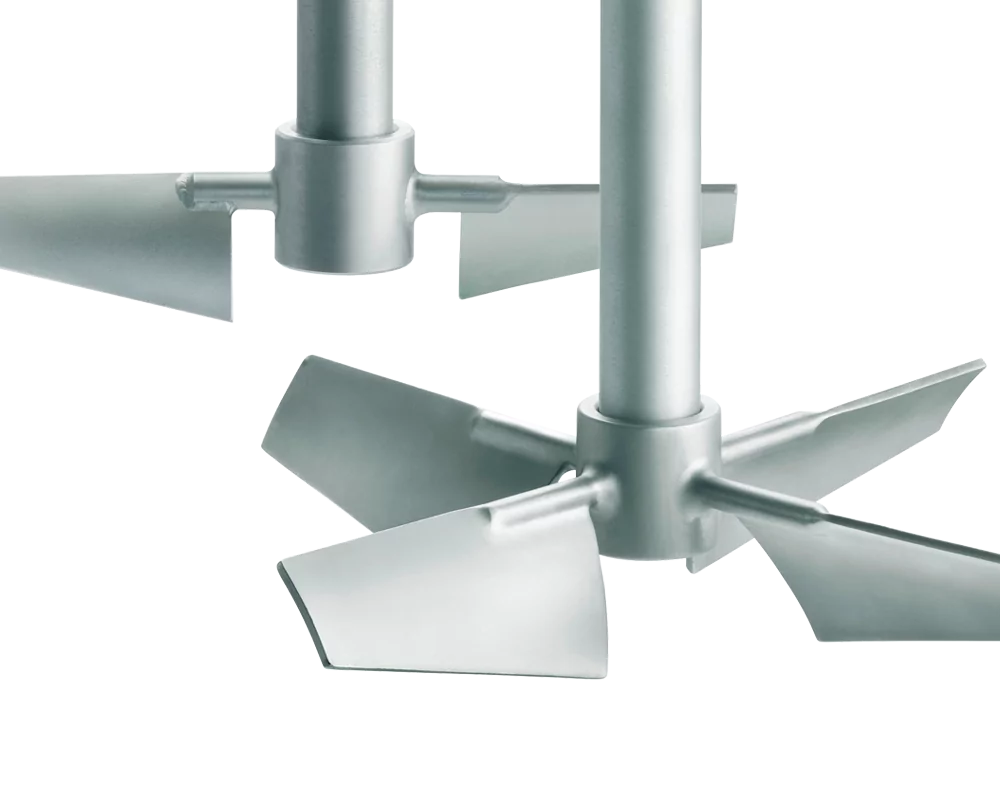

| Impeller-Systems | EKATO high-efficiency impellers and conventional impellers |

| Materials (product wetted) | Carbon steel, rust- and acid resistant steels, nickel-base alloy, Duplex- and Super Duplex steels, titanium und titanium alloys |

| Approval | ATEX 2014/34/EU & GOST TR-ZU 010/2011 |

Additional Services

Lab tests with the original products can be carried out and analyzed in our highly modern laboratory (ELA lab- and pilot-reactors).Our process specialists will help to put the perfect mixing system together, according to your process requirements. CFD-studies, finite element analyses as well as scaling up to industrial scale, complete EKATO’s range of services.

Standard Design

- Two interdependent drives and control units which can be driven with different shaft speeds and directions of rotation.

- Combination of different impeller-systems (for example: EKATO PARAVISC with EKATO VISCOPROP or Dissolver). Versatile modular system which easily adapts to the varying process requirements.

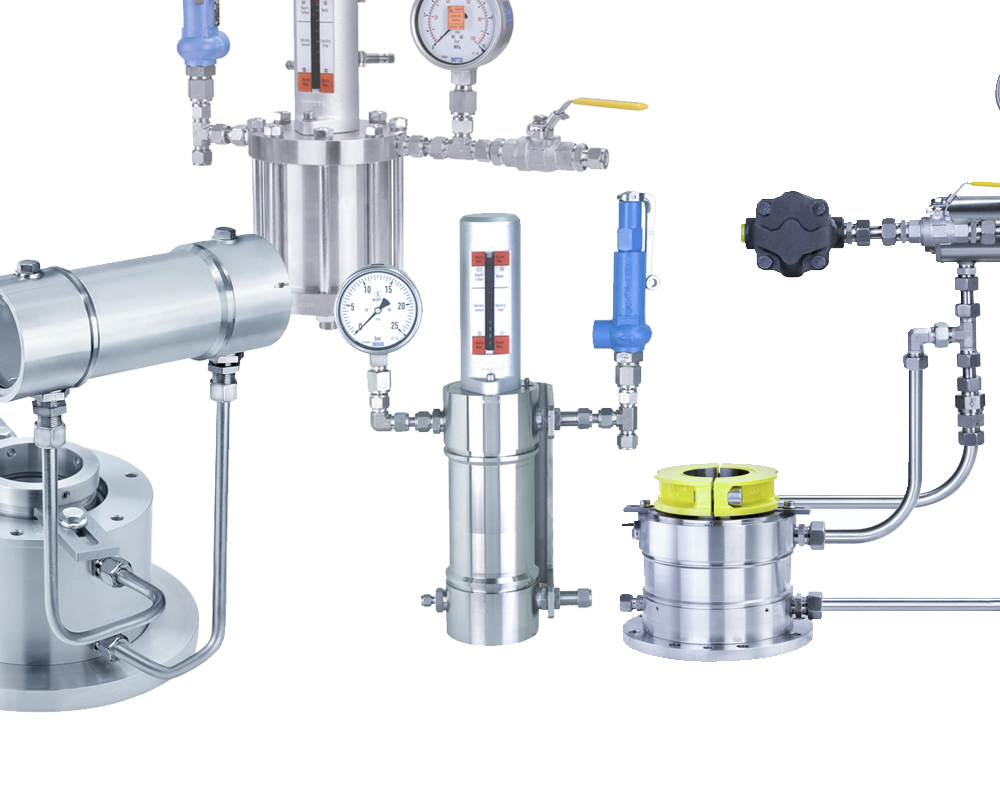

- Sealing systems from seal rings, stuffing boxes up to latest double-acting mechanical seals for the central- and peripheral shaft

Additional Features

- Flexible or rigid scrapers

- Bottom anchor or Z-anchor