Mixing Technology in the Chemical Industry

Bulk/Specialty Chemicals, Polymers, and Bio-Based Products

Agitator Systems in the Processing of Chemical Products

Chemical products are processed using a combination of thermal and mechanical techniques. The agitators used here have a major impact on their quality and properties – like EKATO crystallizers that make it possible to control particle properties. Solid products require drying following crystallization or precipitation. EKATO vacuum contact dryers can complete this step in less time – all without the product being subjected to excessive heat and damaged.

When preparing the chemicals, there is a unique set of challenges when it comes to handling high-viscosity media. Liquids or solids are absorbed or dispersed into a viscous medium using a modular system consisting of an EKATO PARAVISC agitator in combination with wall scrapers or multi-shaft systems to create the mixtures required to produce high-quality products.

EKATO provides a comprehensive know-how for the scale up and design of such complex plants. These engineering services include pilot trials in EKATO’s R&D lab as well as numerical flow simulations (CFD). The mechanical engineering for all components relies on modern tools as the Finite Element Analysis (FEA), which leads to low investment costs without compromises regarding plant safety and reliability.

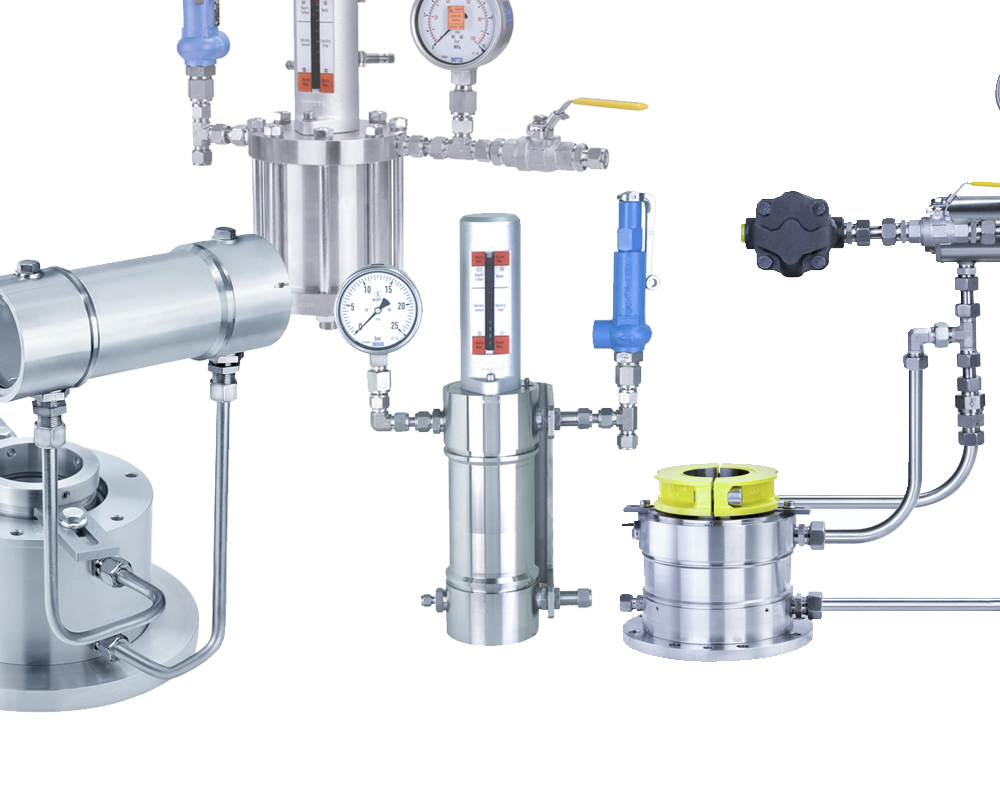

EKATO mechanical shaft seals including the seal supply system ensure the reliable operation of the agitator at all pressure levels. With their long service intervals they are easy to maintain, and the automation level to monitor and control the supply can be adjusted to the operation and safety requirements.

Common Applications in the Chemical Industry:

- Base chemicals

- Fine chemicals

- Specialty chemicals

- Polymers

- Active pharmaceutical ingredients

- Fertilizers