Automatic Seal Supply Systems

Reliable Operation of Mechanical Seals

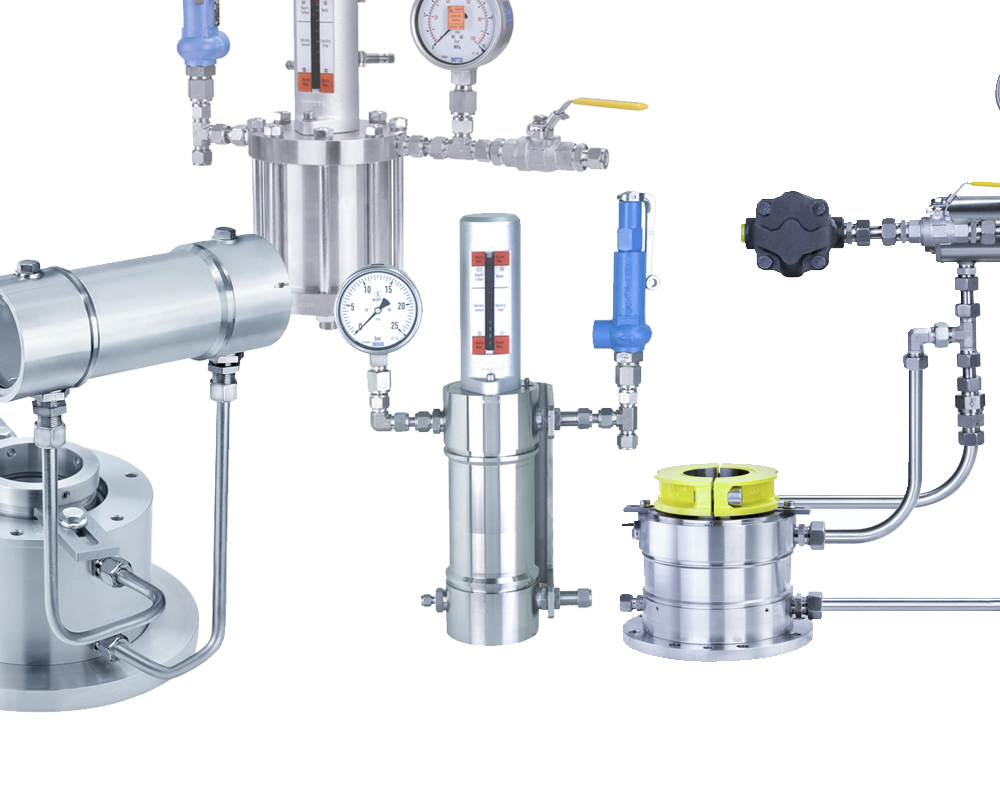

Product Details

The safe operation of the mechanical seal depends on the monitoring and control of the seal pressure system. Automatic supply systems thus guarantee the safe and reliable operation of the seal. A seal is considered technically tight when the pressure in the seal chamber is always higher than the vessel pressure. Therefore, the supply of seal liquid is of primary importance when it comes to safety.

The sealant supply system thus has the following tasks:

- Pressure maintenance: this can be realized with pressure compensators or flow systems. Emergency supply: here an increased leakage at a mechanical seal is compensated for by a compulsory liquid flow so that the agitator can still be operated for a certain time. Cooling: the heat entering from the vessel into the seal and the heat generated by the friction in the seal gap must be continuously dissipated. Flushing: in order to protect the seal rings from corrosive or erosive substances, they are flushed with a liquid that is compatible with the process in the tank and the seal rings themselves. To meet the different requirements, the individual components and the necessary instrumentation are determined according to the present conditions. Supply systems for several agitators for the permanent monitoring of all relevant plant parameters also help to reduce costs. These supply systems are adapted to the local conditions and customer-specific requirements.

- Emergency supply: here an increased leakage at a mechanical seal is compensated for by a compulsory liquid flow so that the agitator can still be operated for a certain time.

- Cooling: the heat entering from the vessel into the seal and the heat generated by the friction in the seal gap must be continuously dissipated.

- Flushing: in order to protect the seal rings from corrosive or erosive substances, they are flushed with a liquid that is compatible with the process in the tank and the seal rings themselves.

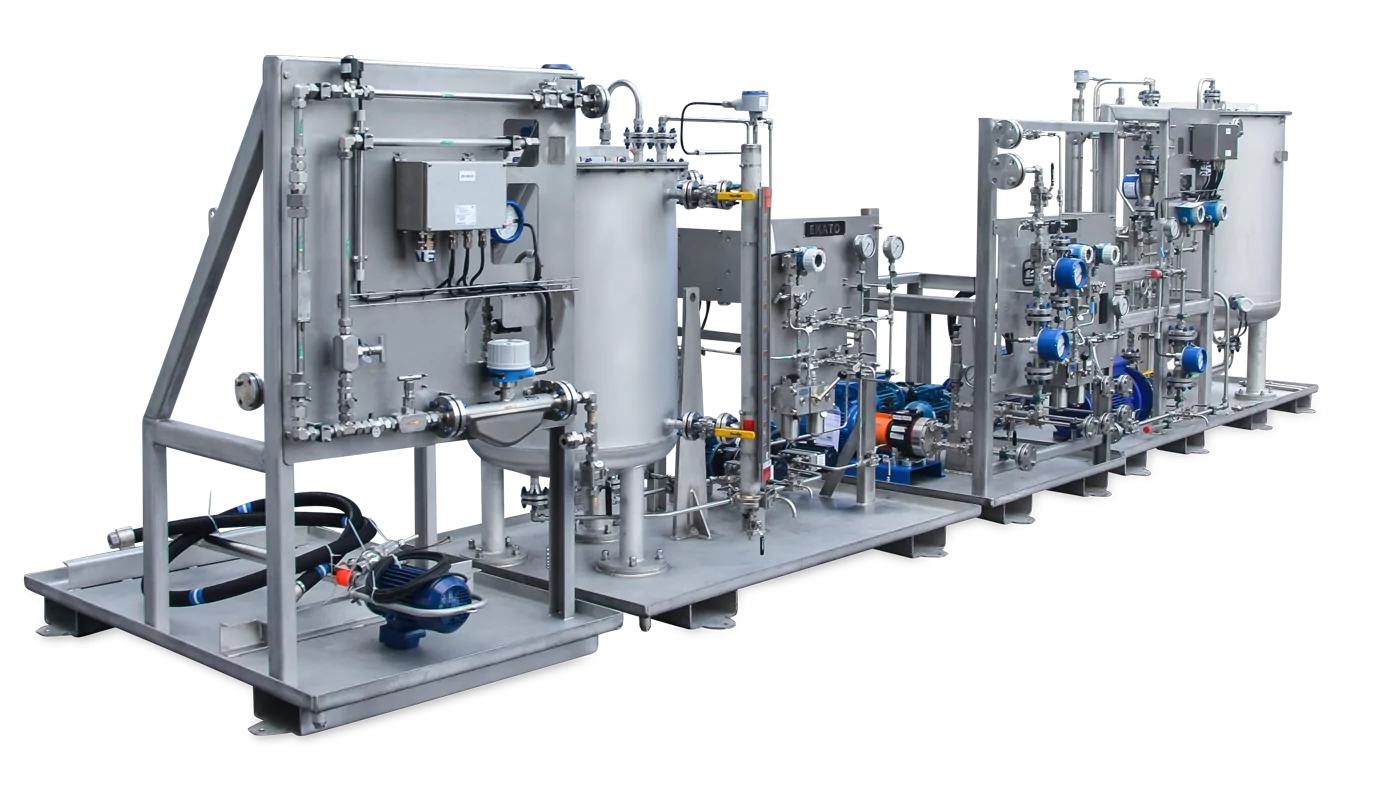

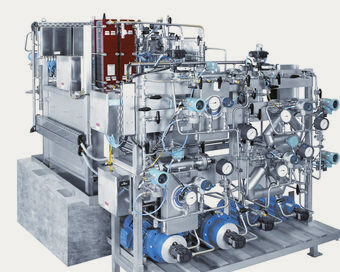

To meet the different requirements, the individual components and the necessary instrumentation are determined according to the present conditions. Supply systems for several agitators for the permanent monitoring of all relevant plant parameters also help to reduce costs. These supply systems are adapted to the local conditions and customer-specific requirements.

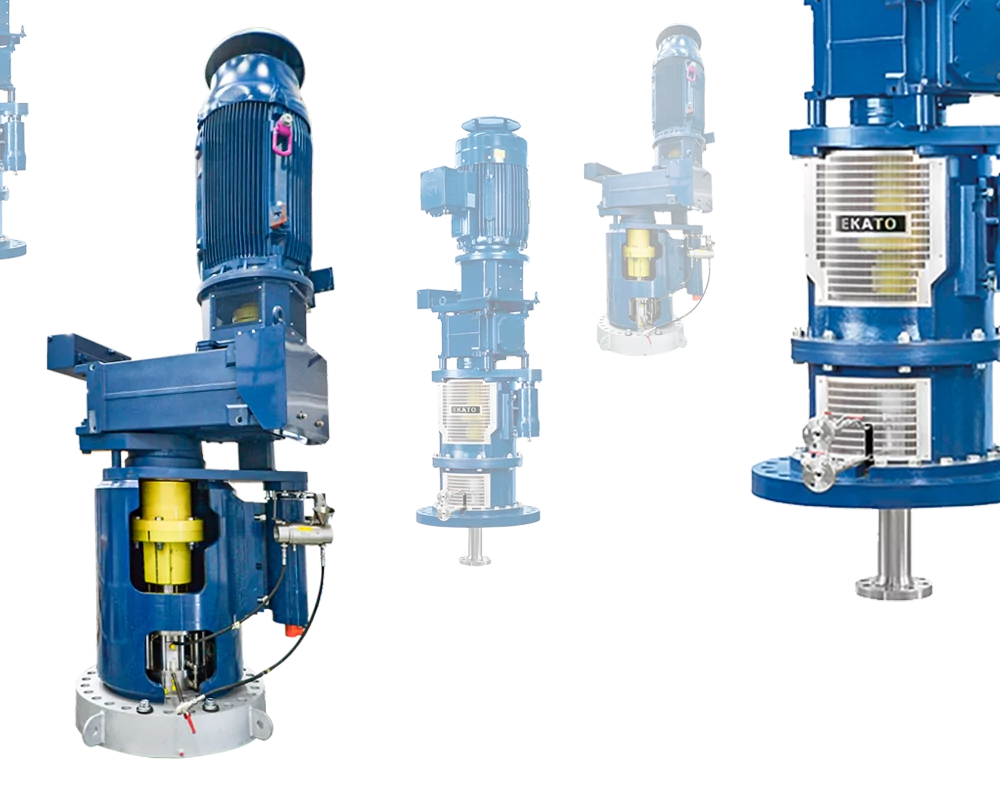

- EKATO seal supply systems and mechanical seals from a single supplier

- The sealing technology and supply systems are specially adapted to the needs of the agitators

- The best solution for any special sealing problem

- Individual instrumentation tailored to customer requirements

Seal Supply Systems

- Automatic refilling and monitoring of the seal liquid

- Ideal cooling of the mechanical seals by the cooling system – even at high process temperatures

- Sufficient protection against contamination by the flushing system – also for special applications

- Reliable operation of mechanical seals thanks to many years of experience with numerous supply systems

- Permanent monitoring of all relevant system parameters such as pressure, temperature, flow, and fill level by means of transmitters or alarm signals

- Our supply systems are designed by experienced engineers

- Adapted to local conditions and customer-specific requirements

- Factory acceptance test (FAT) ensures the perfect functioning of all components